Ensuring Flawless Chip Production: Semiconductor Ultrapure Water Analysis b ICP-OES for the Semiconductor Industry

Maintaining ultrapure water (UPW) integrity is paramount throughout semiconductor production. Even the slightest impurities in this highly deionized water can disrupt delicate chip fabrication processes. At Benchmark Lab, our exhaustive semiconductor ultrapure water analysis services provide essential insights to ensure:

Impeccable Wafer Quality: Through meticulous UPW analysis for trace elements and impurities, we ensure a pristine environment for silicon wafer production, minimizing potential defects.

Optimized Water Treatment Systems: Our analysis aids in monitoring the effectiveness of your water treatment systems, allowing for timely adjustments and optimizations to consistently maintain UPW quality.

Reduced Production Costs: Proactive identification of potential issues through semiconductor water analysis can help prevent costly disruptions and product defects during chip manufacturing.

Impeccable Wafer Quality: Through meticulous UPW analysis for trace elements and impurities, we ensure a pristine environment for silicon wafer production, minimizing potential defects.

Optimized Water Treatment Systems: Our analysis aids in monitoring the effectiveness of your water treatment systems, allowing for timely adjustments and optimizations to consistently maintain UPW quality.

Reduced Production Costs: Proactive identification of potential issues through semiconductor water analysis can help prevent costly disruptions and product defects during chip manufacturing.

Preserving Semiconductor Ultrapure Water Purity for Semiconductor Production

The dependency on semiconductor ultrapure water in semiconductor manufacturing cannot be overstated. This exceptionally deionized water must be free from contaminants, as even the smallest impurity can interfere with chip production processes. Through Benchmark Lab's UPW analysis, we offer insights critical for:

Ensuring Impeccable Wafer Quality: Our detailed semiconductor ultrapure water analysis for contaminants ensures a pristine manufacturing environment, minimizing defect rates.

Optimizing Water Treatment Systems: We monitor and enhance the efficacy of your water treatment solutions to guarantee the consistent quality of semiconductor ultrapure water.

Lowering Production Overheads: Identifying potential issues early through our analysis can prevent expensive production disruptions and defects.

Advanced Water Analysis Methods

Benchmark Lab employs a comprehensive suite of advanced analysis techniques to give you a complete understanding of your semiconductor ultrapure water quality:

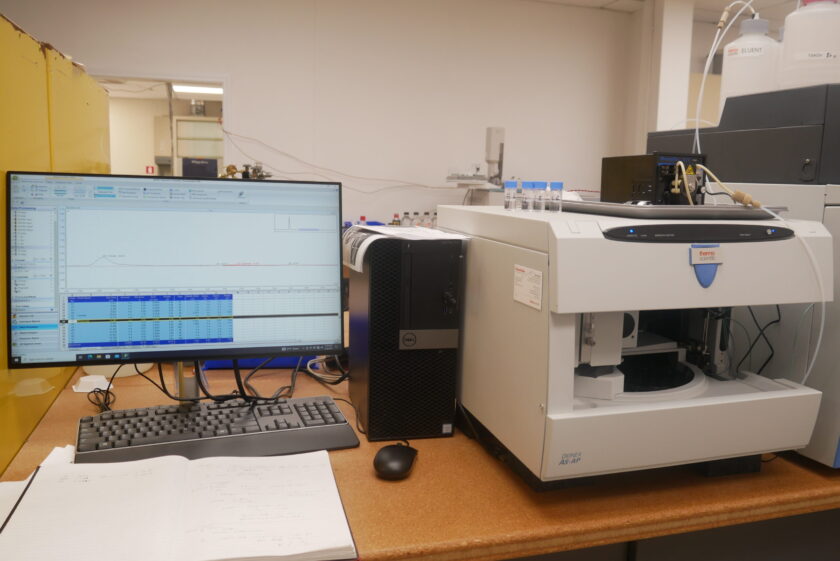

ICP-OES & IC Analysis: With Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES) and Ion Chromatography (IC), we offer unmatched accuracy in detecting trace metals and other contaminants in semiconductor ultrapure water.

TOC Analysis: Our Total Organic Carbon (TOC) analysis is essential for identifying organic contaminants, ensuring semiconductor ultrapure water purity and preventing water system biofouling.

Particle Counting: Utilizing state-of-the-art particle counting technology, we assess the size and quantity of particles in semiconductor ultrapure water, ensuring compliance with semiconductor manufacturing cleanliness standards.

Dedication to Quality and Expertise

Benchmark Lab is committed to delivering precise and detailed data. Our semiconductor ultrapure water analysis reports are accessible in downloadable PDF format, providing a straightforward summary of findings. Our team's extensive knowledge of semiconductor water quality needs, combined with our awareness of the latest industry standards and analysis technologies, ensures our services are second to none.

Partnership for Semiconductor Manufacturing Excellence

Collaborating with Benchmark Lab means securing a dedicated ally in achieving semiconductor manufacturing excellence. Our semiconductor ultrapure water analysis services offer:

Expert Consultation: Discuss your needs with our team for personalized analysis method recommendations.

Tailored Solutions: We adapt our services to meet your unique water quality challenges, enhancing your production efficiency.

Prompt Results: Recognizing the urgency of semiconductor production, we deliver swift analysis outcomes to ensure seamless operations.

Choosing Benchmark Lab means partnering with a leader in semiconductor manufacturing support. Our sophisticated water analysis services are designed to help you maintain optimal water quality, improve production processes, and achieve the best possible chip yields. Reach out to Benchmark Lab to explore how we can elevate your semiconductor manufacturing capabilities.

The dependency on semiconductor ultrapure water in semiconductor manufacturing cannot be overstated. This exceptionally deionized water must be free from contaminants, as even the smallest impurity can interfere with chip production processes. Through Benchmark Lab's UPW analysis, we offer insights critical for:

Ensuring Impeccable Wafer Quality: Our detailed semiconductor ultrapure water analysis for contaminants ensures a pristine manufacturing environment, minimizing defect rates.

Optimizing Water Treatment Systems: We monitor and enhance the efficacy of your water treatment solutions to guarantee the consistent quality of semiconductor ultrapure water.

Lowering Production Overheads: Identifying potential issues early through our analysis can prevent expensive production disruptions and defects.

Advanced Water Analysis Methods

Benchmark Lab employs a comprehensive suite of advanced analysis techniques to give you a complete understanding of your semiconductor ultrapure water quality:

ICP-OES & IC Analysis: With Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES) and Ion Chromatography (IC), we offer unmatched accuracy in detecting trace metals and other contaminants in semiconductor ultrapure water.

TOC Analysis: Our Total Organic Carbon (TOC) analysis is essential for identifying organic contaminants, ensuring semiconductor ultrapure water purity and preventing water system biofouling.

Particle Counting: Utilizing state-of-the-art particle counting technology, we assess the size and quantity of particles in semiconductor ultrapure water, ensuring compliance with semiconductor manufacturing cleanliness standards.

Dedication to Quality and Expertise

Benchmark Lab is committed to delivering precise and detailed data. Our semiconductor ultrapure water analysis reports are accessible in downloadable PDF format, providing a straightforward summary of findings. Our team's extensive knowledge of semiconductor water quality needs, combined with our awareness of the latest industry standards and analysis technologies, ensures our services are second to none.

Partnership for Semiconductor Manufacturing Excellence

Collaborating with Benchmark Lab means securing a dedicated ally in achieving semiconductor manufacturing excellence. Our semiconductor ultrapure water analysis services offer:

Expert Consultation: Discuss your needs with our team for personalized analysis method recommendations.

Tailored Solutions: We adapt our services to meet your unique water quality challenges, enhancing your production efficiency.

Prompt Results: Recognizing the urgency of semiconductor production, we deliver swift analysis outcomes to ensure seamless operations.

Choosing Benchmark Lab means partnering with a leader in semiconductor manufacturing support. Our sophisticated water analysis services are designed to help you maintain optimal water quality, improve production processes, and achieve the best possible chip yields. Reach out to Benchmark Lab to explore how we can elevate your semiconductor manufacturing capabilities.

Frequently Asked Questions

UPW is water that has been purified to remove almost all contaminants, including organic compounds, particles, dissolved gases, and ions. It is essential for processes where purity is critical, such as semiconductor manufacturing.

In semiconductor manufacturing, even minor impurities in water can cause defects in the silicon wafers. Semiconductor ultrapure water ensures a contaminant-free environment for the production of high-quality chips.

Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES) analyzes semiconductor ultrapure water by ionizing the sample with a plasma torch and measuring the emitted light at specific wavelengths, indicating the presence of trace metals and other elements.

Total Organic Carbon (TOC) analysis quantifies the amount of organic compounds in semiconductor ultrapure water. These compounds must be minimized to prevent biofouling and ensure the water's purity and suitability for semiconductor manufacturing.

Particle counting measures the size and concentration of particles in semiconductor ultrapure water. This is vital for semiconductor manufacturing, as particles can lead to defects in the silicon wafers, affecting the performance and yield of the chips.

Quick Contact

If you have any questions or need help, feel free to contact with our team.

Call Us Today:

Send Us Email:

©2024 , All Rights Reserved. Benchmark Lab