Unlock Lithium Extraction Potential: Benchmark Lab Provides Lithium Analysis by ICP-OES Analysis for Oilfield Brines

At the intersection of traditional energy production and the burgeoning demand for renewable resources, Lithium Extraction emerges as a pivotal arena. Benchmark Lab, renowned for its expertise in water analysis, now leads the charge in advancing Lithium Extraction technologies, specializing in lithium analysis by ICP-OES for comprehensive evaluation of lithium brine resources.

Enhancing Lithium Recovery from Oilfield Brines

A valuable resource lies hidden within the byproducts of oil and gas production: lithium. As a crucial component for electric vehicle batteries and renewable energy storage solutions, lithium's importance continues to grow. Through our lithium analysis by ICP-OES services, Benchmark Lab enables oil and gas producers to tap into this lucrative opportunity by:

Determining Lithium Levels: Our sophisticated lithium analysis by ICP-OES offers precise measurements of lithium content, crucial for evaluating the feasibility of Lithium recovery projects.

Identifying Other Elements: Beyond lithium, our comprehensive analysis identifies additional elements and impurities, providing essential data for refining Lithium processes.

Customizing Extraction Approaches: Armed with detailed insights into brine composition, we guide producers in selecting and optimizing Lithium production techniques for superior efficiency and yield.

Tailored Expertise for Efficient Lithium Production

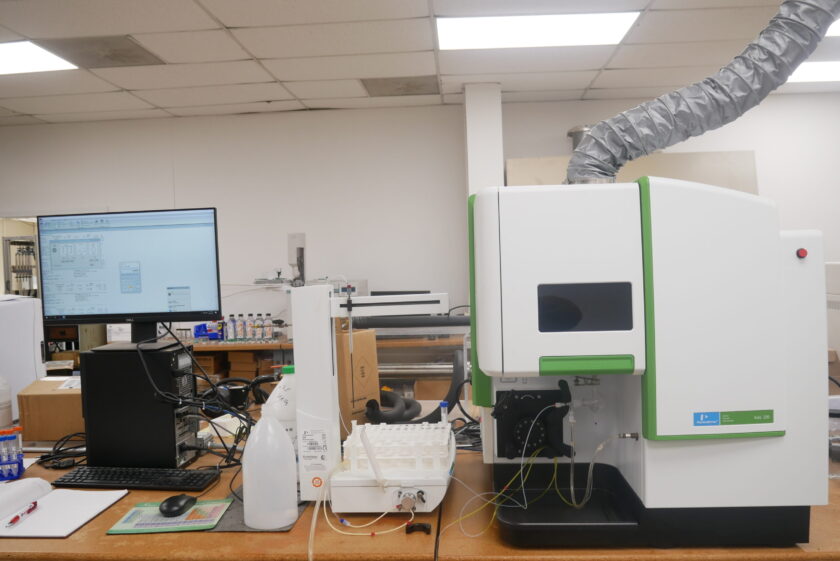

Understanding the unique characteristics of oilfield brines and the intricacies of Lithium production, Benchmark Lab utilizes the latest in analytical technology, including ICP-OES and Ion Chromatography (IC), to deliver:

Precise and Trustworthy Data: Our focus on accuracy ensures that your Lithium production strategies are informed by reliable analyses.

Consultative Support: We offer expert guidance to help interpret analysis outcomes and develop effective Lithium Extraction plans.

Adaptable Services: Our solutions are customized to meet the specific demands of your project, considering factors like brine composition and production scale.

Your Partner in Lithium Resource Development

As the quest for lithium gains momentum, Benchmark Lab is dedicated to enhancing our lithium brine analysis capabilities, ensuring our partners have access to the cutting-edge techniques required for successful Lithium recovery.

Advanced Analytical Equipment: Leverage our top-tier instruments, such as the PerkinElmer Avio 200 ICP OES, for detailed and expansive brine analysis.

Efficient Analytical Process: Our streamlined procedures guarantee swift, actionable results, accelerating your Lithium Extraction initiatives.

Eco-Conscious Approach: We are committed to conducting our analyses with an eye toward environmental responsibility.

Capitalizing on Lithium Opportunities in Produced Water

As lithium demand soars, the oil and gas sector is uniquely positioned to contribute to the renewable energy landscape. Benchmark Lab is your ally in this endeavor, offering the insights needed to make informed decisions on Lithium recovery from produced water.

Step into the energy future with confidence. Reach out to Benchmark Lab to explore how our lithium analysis by ICP-OES services can support your Lithium production objectives.

A valuable resource lies hidden within the byproducts of oil and gas production: lithium. As a crucial component for electric vehicle batteries and renewable energy storage solutions, lithium's importance continues to grow. Through our lithium analysis by ICP-OES services, Benchmark Lab enables oil and gas producers to tap into this lucrative opportunity by:

Determining Lithium Levels: Our sophisticated lithium analysis by ICP-OES offers precise measurements of lithium content, crucial for evaluating the feasibility of Lithium recovery projects.

Identifying Other Elements: Beyond lithium, our comprehensive analysis identifies additional elements and impurities, providing essential data for refining Lithium processes.

Customizing Extraction Approaches: Armed with detailed insights into brine composition, we guide producers in selecting and optimizing Lithium production techniques for superior efficiency and yield.

Tailored Expertise for Efficient Lithium Production

Understanding the unique characteristics of oilfield brines and the intricacies of Lithium production, Benchmark Lab utilizes the latest in analytical technology, including ICP-OES and Ion Chromatography (IC), to deliver:

Precise and Trustworthy Data: Our focus on accuracy ensures that your Lithium production strategies are informed by reliable analyses.

Consultative Support: We offer expert guidance to help interpret analysis outcomes and develop effective Lithium Extraction plans.

Adaptable Services: Our solutions are customized to meet the specific demands of your project, considering factors like brine composition and production scale.

Your Partner in Lithium Resource Development

As the quest for lithium gains momentum, Benchmark Lab is dedicated to enhancing our lithium brine analysis capabilities, ensuring our partners have access to the cutting-edge techniques required for successful Lithium recovery.

Advanced Analytical Equipment: Leverage our top-tier instruments, such as the PerkinElmer Avio 200 ICP OES, for detailed and expansive brine analysis.

Efficient Analytical Process: Our streamlined procedures guarantee swift, actionable results, accelerating your Lithium Extraction initiatives.

Eco-Conscious Approach: We are committed to conducting our analyses with an eye toward environmental responsibility.

Capitalizing on Lithium Opportunities in Produced Water

As lithium demand soars, the oil and gas sector is uniquely positioned to contribute to the renewable energy landscape. Benchmark Lab is your ally in this endeavor, offering the insights needed to make informed decisions on Lithium recovery from produced water.

Step into the energy future with confidence. Reach out to Benchmark Lab to explore how our lithium analysis by ICP-OES services can support your Lithium production objectives.

Frequently Asked Questions

The economic viability of extracting lithium from oilfield brine largely depends on several factors, including the concentration of lithium, the volume of brine available, extraction technology, lithium market prices, and operational costs. Generally, a lithium concentration of at least 100 parts per million (ppm) or 100 milligrams per liter (mg/L) in brine is often considered a starting point for potentially viable extraction on a commercial scale. However, with advancements in extraction technologies and increases in lithium prices, lower concentrations might become economically feasible in the future. It's crucial for companies to conduct comprehensive feasibility studies, including detailed lithium analysis by ICP-OES, to accurately assess the economic potential of their specific brine resources.

ICP-OES (Inductively Coupled Plasma Optical Emission Spectroscopy) is crucial in lithium brine analysis due to its ability to provide precise and accurate measurements of lithium concentrations in brine samples. This technology enables the detection of trace amounts of lithium and other relevant elements, facilitating the assessment of brine's potential for Lithium Extraction. The accuracy and reliability of ICP-OES analysis ensure that Lithium Extraction projects are based on solid data, optimizing resource recovery and process efficiency.

Customizing Lithium recovery strategies according to the specific composition of the brine is vital because each lithium brine source can vary significantly in terms of lithium concentration, presence of impurities, and other elemental compositions. Tailoring the extraction process ensures that the methods used are the most effective for the particular characteristics of the brine, thereby maximizing lithium yield, minimizing environmental impact, and optimizing operational costs.

Benchmark Lab's approach to lithium brine analysis supports sustainable Lithium production practices by offering detailed insights into brine composition, which aids in the development of extraction processes that are both efficient and environmentally friendly. By identifying the most effective extraction methods and potential environmental impacts early on, Benchmark Lab helps producers implement strategies that minimize waste, reduce the use of harmful chemicals, and ensure the responsible use of water resources, contributing to the overall sustainability of Lithium Extraction projects.

Advanced analytical technologies like ICP-OES offer numerous advantages to oil and gas producers exploring Lithium recovery, including high sensitivity and specificity for detecting lithium and other elements, rapid analysis times, and the ability to handle a wide range of sample types. These technologies provide accurate and reliable data that is critical for evaluating the economic viability of Lithium Extraction projects, designing the extraction process, and monitoring the quality of the extracted lithium.

Quick Contact

If you have any questions or need help, feel free to contact with our team.

Call Us Today:

Send Us Email:

©2024 , All Rights Reserved. Benchmark Lab