Optimize Oil and Gas Pipeline Performance with Benchmark Lab's Houston Fluid Dynamic Testing Services

Oil and Gas Pipeline Dynamic Testing Services by Benchmark Lab Houston

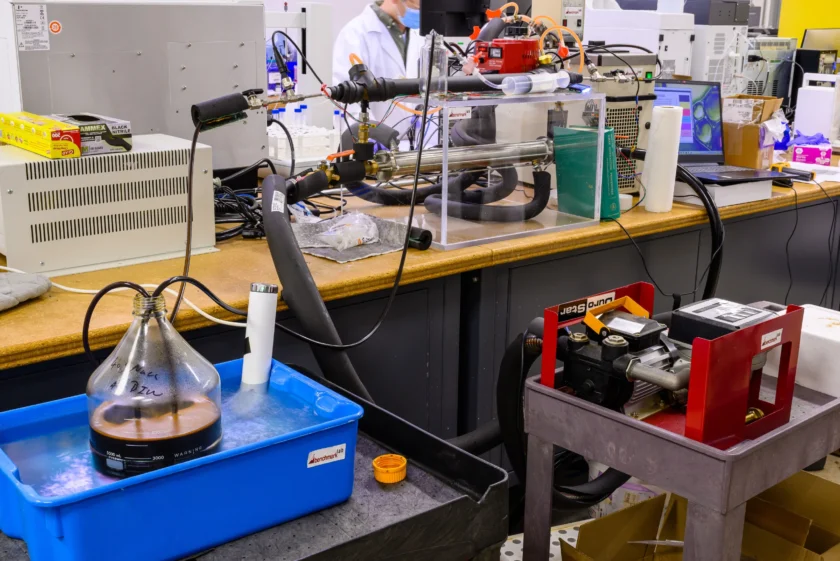

Benchmark Lab is at the forefront of delivering specialized pipeline fluid dynamic testing services, crucial for the oil & gas pipeline industry, as well as other sectors that rely on efficient fluid transportation systems. Our services, equipped with state-of-the-art flowloop systems and analytical technologies, are designed to optimize oil & gas pipeline operations by evaluating the effectiveness of drag reduction agents, assessing scaling tendencies, measuring water content, and testing paraffin wax deposition. Additionally, our research extends into critical areas such as corrosion, multiphase flow behavior, and asphaltene deposition, offering comprehensive insights to enhance oil & gas pipeline efficiency and integrity.

Drag Reduction Inhibitor Testing (DRA) Flowloop

Our DRA flowloop testing service evaluates the efficiency of drag-reducing agents in oil & gas pipeline systems, enabling operators to significantly enhance flow rates and reduce operational costs. This test is pivotal for selecting the most effective DRAs and optimizing their dosing strategies for oil and gas pipelines.Scaling Testing Flowloop

The scaling testing flowloop service is designed to simulate oil & gas pipeline conditions and assess the scaling tendencies of fluids under various operational parameters. This testing helps in identifying potential scaling issues and evaluating the effectiveness of scaling inhibitors, ensuring the longevity and reliability of oil & gas pipeline systems.Water Content Measurement using Karl Fischer

We employ the Karl Fischer titration method to accurately measure the water content in oil and gas pipeline fluids. This crucial analysis helps in understanding the potential for corrosion, hydrate formation, and scaling, facilitating better water management strategies within the oil & gas pipeline.Paraffin Wax Flowloop Testing

Our paraffin wax flowloop testing service assesses the deposition tendencies of paraffin wax in oil and gas pipeline systems, offering insights into the effectiveness of wax inhibitors and thermal management strategies. This testing is essential for preventing blockages and maintaining smooth operations in oil & gas pipelines.Low Pressure CO2 Wet Gas Flow Loop

This flow loop simulates conditions in oil and gas pipelines exposed to wet gas environments under low pressure, particularly with CO2. Testing in this loop helps understand corrosion dynamics and gas behaviors, crucial for designing corrosion-resistant materials and corrosion inhibitors for oil & gas pipelines.Oil Water Emulsion Corrosion Flow Loop

Our oil water emulsion corrosion flow loop is specially designed to test the corrosion rates and mechanisms in oil and gas pipeline systems transporting oil-water emulsions. This setup helps in evaluating the long-term effects of mixed fluid streams on oil & gas pipeline materials, assisting in the development of more robust corrosion management strategies.Heavy Oil Heating Friction Reducer Flow Loop

The heavy oil heating friction reducer flow loop tests the efficiency of friction reducers in oil and gas pipelines transporting heated heavy oil. This loop helps in optimizing the flow of viscous oils, reducing the energy required for transportation, and minimizing wear and tear on oil & gas pipeline materials.Frequently Asked Questions

This loop is designed to simulate environments where oil and gas pipelines are exposed to wet gas conditions at low pressures, particularly with CO2. This testing is crucial for understanding how different materials react to these specific conditions, helping in the development of effective corrosion inhibitors and the selection of materials that are resistant to corrosion, which is vital for maintaining pipeline integrity and operational efficiency.

This flow loop is essential for assessing the corrosion rates and mechanisms that occur in oil and gas pipelines transporting oil-water emulsions. By understanding the interaction between oil and water phases and their impact on the pipeline materials, this testing aids in the development of more effective corrosion management strategies, ensuring the longevity and reliability of oil and gas pipeline infrastructure.

This flow loop tests the effectiveness of friction reducers in oil and gas pipelines transporting heated heavy oil. This testing is particularly beneficial for optimizing the flow of viscous oils, reducing the energy required for transportation, and minimizing wear and tear on oil and gas pipeline materials. Insights from this loop enable operators to enhance operational efficiency and prevent blockages.

Benchmark Lab's services are critical because they provide comprehensive evaluations of how oil and gas pipeline systems handle different fluids and conditions. From testing drag reduction agents and scaling tendencies to assessing wax deposition and corrosion, our services ensure that oil and gas pipeline materials and operations are optimized for safety, efficiency, and durability. Our state-of-the-art flow loops offer targeted insights that support informed decision-making and strategic planning in oil and gas pipeline management.

Quick Contact

If you have any questions or need help, feel free to contact with our team.

Call Us Today:

Send Us Email:

©2024 , All Rights Reserved. Benchmark Lab