Optimizing Boiler Efficiency: Benchmark Lab's Scale Formation in Boiler Testing Expertise

At Benchmark Lab, addressing scale formation in Boiler is our specialty, ensuring peak performance for industries reliant on these critical systems. Scale buildup is a significant issue for sectors like oil and gas, water treatment, and broader industrial processes, leading to reduced efficiency and higher operational costs. Leveraging state-of-the-art diagnostic tools and a profound understanding of water chemistry, we deliver unmatched scale analysis and prevention services tailored to your unique needs.

Evaluating Water Chemistry for Scale Management: Our comprehensive water quality analysis is foundational in combatting Scale formation in boiler. By identifying the concentrations of scaling ions such as calcium, magnesium, barium, and sulfate, we provide the essential first step in recognizing and mitigating potential scale buildup risks in boilers. This proactive approach is key to maintaining system efficiency and avoiding costly downtime.

Advancing with Predictive Scale Modeling- Scale Tendency Test: Our scale tendency assessment modeling utilizes sophisticated software to forecast the likelihood and severity of scale formation in boiler under various conditions. This predictive capability allows for strategic scale management planning and the optimization of chemical treatment processes. By anticipating scale formation, you can effectively safeguard your systems against the common pitfalls of scale buildup, ensuring continued operational excellence.

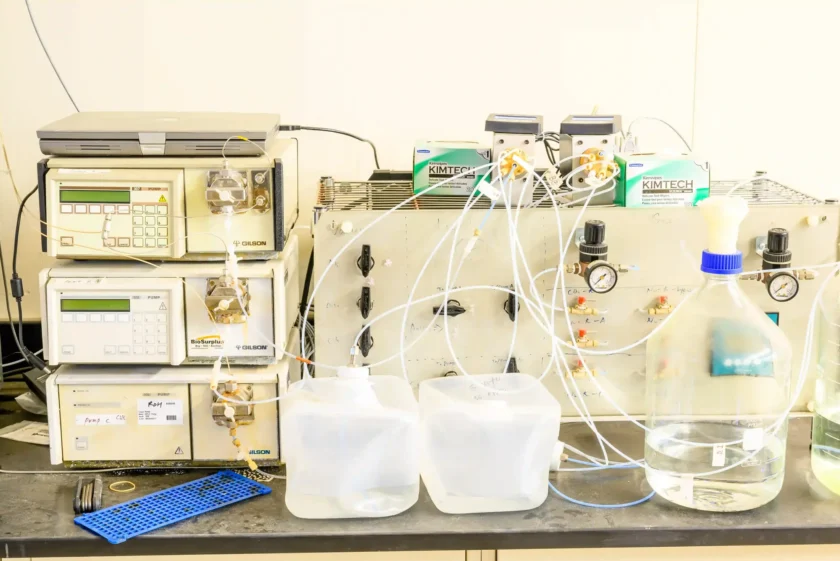

Evaluating Scale Inhibitor Performance Benchmark Lab's scale inhibitor testing encompasses both static and dynamic methodologies to offer a comprehensive evaluation of chemical inhibitor effectiveness in preventing scale formation in boiler. Our static bottle test method assesses inhibitor performance under controlled conditions, providing insights into optimal dosing rates. For a more real-world assessment, our dynamic scale flow loop simulates actual system conditions, offering invaluable data on how well inhibitors perform in live scenarios. This dual approach ensures that your boiler systems remain scale-free and operate at maximum efficiency.

Determining Scale Onset Conditions Through precise testing, we identify the scale onset pressure and temperature (SOPT), critical metrics for understanding when and under which conditions scale formation in boiler" begins to form. This information is instrumental in devising effective scale management and prevention strategies tailored to your operations. By pinpointing these thresholds, we equip you with the knowledge to proactively address scale formation, enhancing the longevity and efficiency of your boilers.

Advancing with Predictive Scale Modeling- Scale Tendency Test: Our scale tendency assessment modeling utilizes sophisticated software to forecast the likelihood and severity of scale formation in boiler under various conditions. This predictive capability allows for strategic scale management planning and the optimization of chemical treatment processes. By anticipating scale formation, you can effectively safeguard your systems against the common pitfalls of scale buildup, ensuring continued operational excellence.

Evaluating Scale Inhibitor Performance Benchmark Lab's scale inhibitor testing encompasses both static and dynamic methodologies to offer a comprehensive evaluation of chemical inhibitor effectiveness in preventing scale formation in boiler. Our static bottle test method assesses inhibitor performance under controlled conditions, providing insights into optimal dosing rates. For a more real-world assessment, our dynamic scale flow loop simulates actual system conditions, offering invaluable data on how well inhibitors perform in live scenarios. This dual approach ensures that your boiler systems remain scale-free and operate at maximum efficiency.

Determining Scale Onset Conditions Through precise testing, we identify the scale onset pressure and temperature (SOPT), critical metrics for understanding when and under which conditions scale formation in boiler" begins to form. This information is instrumental in devising effective scale management and prevention strategies tailored to your operations. By pinpointing these thresholds, we equip you with the knowledge to proactively address scale formation, enhancing the longevity and efficiency of your boilers.

Frequently Asked Questions

Scale formation in boilers typically results from the precipitation of mineral compounds found in the water, primarily calcium, magnesium, barium, and sulfates. These minerals accumulate on the boiler's inner surfaces as water heats up and evaporates, leaving behind hard, insulating deposits. This process is influenced by various factors, including the water's mineral content, operational temperatures, and the water's pH level.

Scale formation in boilers refers to the accumulation of hardened mineral deposits on the internal components, especially around heat transfer areas. This phenomenon occurs when water, containing dissolved minerals, is heated within the boiler, causing the minerals to precipitate out and adhere to the metal surfaces. The resulting scale significantly impedes heat transfer, affecting the boiler's efficiency and operation.

To prevent scale formation in boilers, a multifaceted approach involving water treatment and regular maintenance is essential. Employing water softening processes, applying scale inhibitors, and maintaining optimal pH levels can significantly reduce mineral precipitation. Regularly conducting boiler maintenance, such as cleaning and monitoring water chemistry, also plays a crucial role in preventing scale buildup and ensuring efficient boiler operation.

Preventing scale formation in boilers is crucial for several reasons. Scale acts as a thermal insulator, hindering efficient heat transfer, which can lead to increased fuel consumption and higher operating costs. Additionally, scale buildup can cause uneven heating and stress on the boiler's structure, potentially leading to premature wear, failures, or hazardous operating conditions. Ensuring a scale-free boiler enhances safety, operational efficiency, and the longevity of the equipment.

Accessing Benchmark Lab's Comprehensive Scale Analysis Services is simple. Contact us today to discuss your analytical needs, and our team of experts will work with you to develop a customized analysis plan that meets your requirements and objectives.

Quick Contact

If you have any questions or need help, feel free to contact with our team.

Call Us Today:

Send Us Email:

©2024 , All Rights Reserved. Benchmark Lab